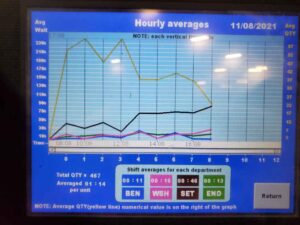

TruCount

I designed, programmed, and installed a timer counting system to help identify where the bottle neck is on the line. Each station is monitored and their average time of each station is adjusted only if the line is waiting on them on that specific unit that is coming down the line. Allowing for an accurate measurement of wait times per station. If the line didn’t wait on that specific station but on another station then their average would go down not up. A supervisor can look up at the main display

and see which station has the highest avg wait time and check to see how it can be improved. There are 4 stations this keeps track of

- BEN = Bender & Butyl Operator

- SET = Frame Setter

- WSH = Washer Loader

- END = Robot Operator

and reports are available on the main HMI that shows a line graph with updates each hour.

The overall average unit build time is also calculated along with the quantity. The Robot horn time and purge time is also recorded

We record this to get an idea if the operator is purging the robot per instructions and if the operator is purging quickly enough or waiting too long while the horn blares.

Previous Post

Previous Post Next Post

Next Post